Automatic Truck & Container Loading System

Automatic Truck & Container Loading System Manufacturer in Australia

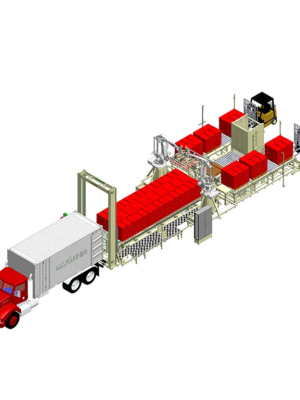

Automatic Truck & Container Loading System (ATCLS) by Alligator Automations transforms the way goods are prepared for dispatch. By drastically reducing loading time and dependence on manual labor, the system enhances operator safety while maximizing overall operational capacity. Designed with efficiency and ease of use in mind, it seamlessly integrates into modern logistics workflows.

In today’s competitive global market, the ATCLS sets a new benchmark for dispatch efficiency, directly improving the speed and reliability of goods movement. Tasks that traditionally require significant manpower and time—such as loading 600 bags, which can take up to an hour manually are completed in just 20 to 30 minutes using the automated system. This results in higher productivity, smoother operations, and reduced logistical bottlenecks across both truck and container loading applications.

Automatic Truck & Container Loading System Manufacturer in Australia

Automatic Truck Loading System (ATLS) by Alligator Automations reimagines how goods are prepared for transport. It significantly reduces both loading times and the need for manual labor while simultaneously enhancing operator safety and operational capacity. The system is designed to streamline operations and make it user-friendly.

In the competitive global market, the ATLS sets a new standard for dispatch efficiency, directly impacting the flow of goods. Manually loading 600 bags could take up to an hour, but the ATLS brings it to just 20 to 30 minutes, upping productivity and smoothing operational challenges.

Precision • Innovation • Efficiency

Industry Leaders in Packaging Automation – Our Impact

Specifications

Maximum load weight on loading platform

10 T – 40 T

Load platform size in length

5 – 10 Mtr (customizable)

Loading platform size in width

2–2.5 Mtr (customizable)

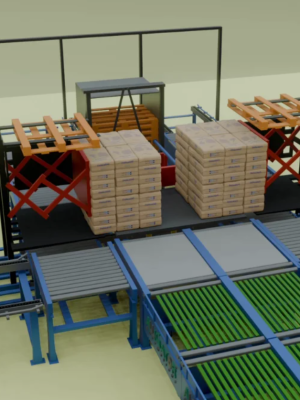

Load preparation

Manual by forklift

Robotic de-palletizing

Load tilter

Hybrid load preparation

(Various options available as per user requirement and application in hand)

Loading platform height adjustment

Customizable up to +/-300mm

Loading platform lateral movement

Customizable up to +/-150mm

Loading per hour

2-3 truck & container per hour

Type of operation

Features

- Automatic operations

- Utilizes a scanning system controlled by dedicated software to guarantee precise alignment of the loading system with the trailer

- Adaptability to different truck & container types

- IoT enabled system

- Data logging system

- Data integration at different levels

- Achieves a 300-400% boost in efficiency compared to conventional manual truck & container loading

- Automates loading for standard, unmodified trailers or containers without the need for any modifications

- Fast loading cycle of less than 10 minutes

- Reduces truck & container turnaround time at the dock

- Enhances workplace safety for both employees and products

- Can operate in any direction, i.e., left, right, up & down, forward & reverse

- High service life and sophistication

Fast returns on investment (ROI)

Add Ons

- Auto rejection – in case identification needed

- Online check weighing system

Get In Touch

Have questions or need a customized automation solution? We’re here to help! Reach out to us for expert guidance, tailored solutions, and seamless support. Whether it’s inquiries, collaborations, or service requests, our team is ready to assist you. Contact us via phone, email, or visit our office—let’s drive efficiency and innovation together!

Request A Call Back

Trusted by Industry Leaders Worldwide

Meet Our Valued Clients